What is Yarn Dyed Fabric?

Yarn-dyed fabric is a type of textile that has undergone a unique dyeing process before it is woven into the fabric. Unlike piece-dyed fabric, where the fabric is dyed after it has been woven, yarn-dyed fabric has its individual yarns dyed in specific colors before weaving. This method allows for greater color variety, intricate patterns, and a higher level of design flexibility, making it a popular choice in fashion, interior design, and other textile applications. In this article, we’ll explore the process, benefits, types, and applications of yarn-dyed fabric.

How is Yarn Dyed Fabric Made?

The process of creating yarn-dyed fabric involves several key stages, including dyeing, weaving, and finishing. Below, we’ll explain each stage in detail.

Dyeing

The first step in the production of yarn-dyed fabric is the dyeing of the yarns. The yarns are dyed individually before they are woven into the fabric. There are various dyeing methods used in yarn dyeing, such as skein dyeing, package dyeing, and beam dyeing. In skein dyeing, the yarns are wound into large skeins and then dyed in a dye bath. In package dyeing, the yarns are wound onto a perforated tube and dyed in a dye bath under pressure, allowing for greater color penetration. Beam dyeing is typically used for large-scale industrial production, where the yarn is dyed in bulk using a cylindrical beam.

The dyeing process can involve a range of dyeing methods, from natural dyes like indigo and cochineal to synthetic dyes that offer more vibrant and long-lasting colors. The color is usually fixed in the yarn to ensure color fastness, meaning that the dye won’t fade or bleed when the fabric is washed.

Weaving

Once the yarns are dyed, they are ready to be woven into fabric. Weaving techniques such as plain weave, twill weave, and satin weave can be used to create various fabric textures and patterns. The woven fabric is constructed by interlacing two sets of yarns: the warp yarns, which run lengthwise, and the weft yarns, which run crosswise. The way the yarns are arranged and interwoven determines the fabric’s final texture, durability, and appearance.

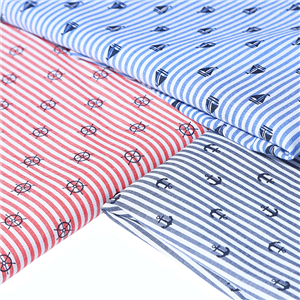

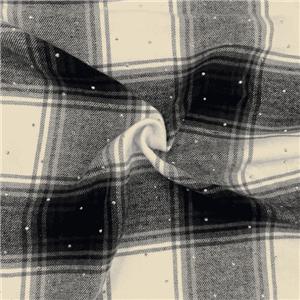

Since the yarns are already dyed, the weaving process often results in intricate fabric patterns that have depth and dimension. These patterns can be as simple as stripes or as complex as checks, plaids, or houndstooth.

Finishing

After the fabric is woven, it goes through a finishing process that can include various treatments to enhance the fabric’s appearance and performance. This can include washing, pressing, softening, or adding a special coating to the fabric to improve its texture, water resistance, or durability. The finishing process also helps to lock in the colors, ensuring that the dyeing remains vibrant and long-lasting.

Yarn Dyeing Process

Weaving Process

Finishing Process

How to Identify Yarn Dyed Fabric?

Identifying yarn-dyed fabric is relatively simple once you understand the characteristics that distinguish it from other types of fabric. Here are some key identifiers:

1. Visible Color Pattern: The most noticeable feature of yarn-dyed fabric is its consistent color pattern that runs throughout the entire fabric, visible from both the front and the back. The woven fabric will have distinct color changes, such as stripes, checks, or plaids, that are inherent in the yarns themselves.

2. Texture: Since yarn-dyed fabrics often have different color yarns woven together, they tend to have a more textured feel than piece-dyed fabrics.

3. Edge Fraying: If you examine the edges of the fabric closely, you may notice that the frayed edges show a consistent color pattern, indicating that the yarns themselves have been dyed before being woven.

Types of Yarn Dyed Fabric

Yarn-dyed fabric comes in several captivating types, each with its unique charm and characteristics.

One popular type is plaid or checkered fabric. Often used in shirts and home textiles, it features a pattern created by alternating colored yarns woven together.

Another variety is houndstooth, which showcases a distinctive broken check design. This classic style adds an elegant touch to fashion apparel and accessories.

Denim also falls under this category when the yarn is dyed before weaving. The result is rich color variations that make denim appealing for jeans and jackets.

Twill fabrics like gabardine offer durability while showcasing diagonal patterns that add texture and depth to garments. Each type of yarn-dyed fabric opens up endless creative possibilities for designers and manufacturers alike.

Benefits of Yarn Dyed Fabric

Yarn-dyed fabric offers several advantages, including:

1. Durability: The dyeing process ensures that the colors are deeply embedded in the yarns, making the fabric more durable and resistant to fading compared to piece-dyed fabric.

2. Color Variety: Since each individual yarn is dyed before weaving, yarn-dyed fabric allows for a wide range of color combinations and intricate patterns.

3. Long-lasting Quality: Yarn-dyed fabrics retain their shape and color much longer, making them a great investment for both fashion and functional uses.

4. Versatility: Yarn-dyed fabrics can be used for various applications, including apparel, home textiles, and even industrial textiles, thanks to their strength and aesthetic appeal.

Applications of Yarn Dyed Fabric

Yarn-dyed fabric boasts a wide range of applications across various industries. One of its most prominent uses is in fashion apparel. Designers often favor this type of fabric for its rich colors and intricate patterns that maintain their vibrancy even after multiple washes.

Home textiles also benefit greatly from yarn dyed fabrics. Curtains, upholstery, and bed linens made from these materials offer both durability and aesthetic appeal, enhancing the overall ambiance of living spaces.

Sportswear manufacturers appreciate yarn-dyed fabrics for their breathability and moisture-wicking properties. This makes them ideal for athletic clothing that requires comfort and performance.

Additionally, quilting enthusiasts love using yarn-dyed cotton due to their distinctive designs. These fabrics add depth to quilts while providing lasting quality.

From everyday garments to specialized products, the versatility of yarn-dyed fabric continues to shine in diverse markets worldwide.

Sustainability of Yarn Dyed Fabric

Yarn-dyed fabrics can be more sustainable than other types of fabric, particularly when made from natural fibers like cotton, linen, or wool. These fabrics are often more durable and require fewer resources over time than piece-dyed fabrics. Additionally, many yarn-dyed fabrics are made using sustainable dyeing methods that reduce water usage and minimize environmental impact.

Care for Your Yarn Dyed Fabric

To extend the life of your yarn-dyed fabric, proper care is essential. Here are some tips:

· Wash with cold water to preserve color integrity.

· Avoid bleaching or harsh detergents that can fade the colors.

· Air dry rather than using high-heat drying methods.

· Iron on low heat, especially if the fabric is made from natural fibers like cotton or linen.

What are the Differences Between Yarn-dyed Fabric and Piece-dyed Fabric?

The key difference between yarn-dyed fabric and piece-dyed fabric is the dyeing process. In yarn-dyed fabric, the yarns are dyed before weaving, allowing for intricate patterns and greater colorfastness. In contrast, piece-dyed fabric is dyed after it is woven, often resulting in less vibrant colors and simpler patterns.

What are the Differences Between Yarn-dyed Fabric and Printed Fabric?

While both yarn-dyed fabric and printed fabric can have patterns, they differ in how the design is applied. Yarn-dyed fabric features designs woven into the fabric through colored yarns, creating a more durable, long-lasting pattern. Printed fabric, on the other hand, has a design applied to the surface of the fabric using printing techniques, which can result in less durability and potential fading over time.

Conclusion

Yarn-dyed fabric is a versatile, durable, and aesthetically pleasing choice for a wide variety of applications, from fashion to home textiles and industrial uses. Whether you’re looking for vibrant patterns, long-lasting quality, or sustainable materials, yarn-dyed fabrics provide a wealth of benefits.

Honry Fabric, as a reputable woven fabric manufacturer, specializes in high-quality yarn-dyed fabrics that cater to a wide range of industries. By focusing on advanced dyeing techniques and sustainable practices, Honry Fabric ensures that their products meet the highest standards of quality while contributing to the overall sustainability of the textile industry. Whether you are seeking materials for fashion, home textiles, or industrial applications, Honry Fabric provides custom-woven fabric solutions tailored to your specific needs.